BUMP

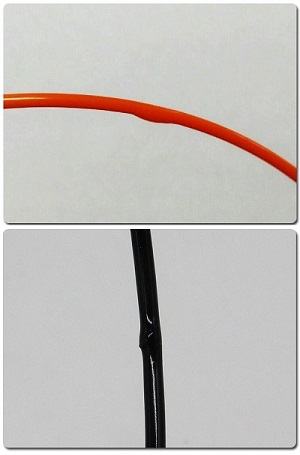

A bump is a spot on the filament with the length of 2~5mm and the diameter may exceed 2.0mm. It is one of the reasons that cause the filament blocking in the feeding tube. The causes of the bump can be either from the gel content inside the raw material or mistakes during the filament extrusion process. Gel problems in the raw material are rather complicated that filament manufacturer cannot do anything about it. Therefore, a good source of premium raw materials is very important.

A bump is a spot on the filament with the length of 2~5mm and the diameter may exceed 2.0mm. It is one of the reasons that cause the filament blocking in the feeding tube. The causes of the bump can be either from the gel content inside the raw material or mistakes during the filament extrusion process. Gel problems in the raw material are rather complicated that filament manufacturer cannot do anything about it. Therefore, a good source of premium raw materials is very important.

For extrusion mistakes, there are a couple of reasons that cause bumps during extrusion.

1. Contamination with different materials. For example, during shifting materials from ABS to PLA, the technician omits the process to clean the screw completely. There are dead spots in the extruder. If the compatibility of these two materials is not so good, the bumps on the filament can be formed. Our standard operation procedure(SOP) is to pull the screw out of the extruder for a complete cleanup and inspection before shifting to other materials.

2. Contamination of other impurities during the pigment mixing or extrusion process. We prevent this possibility by purifying the air in the workshop and applying stainless steel filter screen before extrusion head.

3. Improper setup of extrusion temperatures or poor thermal stability that cause crosslinking or overheating of materials and additives. Correct temperature-setup and routine facility-maintenance are required to prevent these problems.

With the application of premium raw materials and SOPs, we have minimized the possibilities of bumps. However, we found that these precautionary steps are not enough and bumps can happen occasionally due to gel issues of raw materials. Therefore, we applied a complete check-up with laser diameter instrument and mechanical screening device during filament winding process to reach the 100% bump-free standard.

BUBBLE

Bubbles are majorly caused by humidity inside the raw materials. The procedures of thorough pre-drying of materials and testing dryness by an instrument should be implemented.

Friendly Links :

Copyright © 2015-2018 Shenzhen Color Rich 3D Technology Co., Ltd..All Rights Reserved.

online service