Most of the thermoplastic resin can be extruded in filament form. However, without modifications, only a few of them meet the demands of 3D printing. Below is a list of properties that are very important to FDM 3D printing technology:

MELT FLOW INDEX(MFI)

The definition of the melt flow index from Wikipedia: "The melt flow index (MFI) is used to measure the flow rate of a melted thermoplastic polymer. It is defined as the mass of polymer, in grams, flowing in ten minutes through a capillary of a specific diameter and length by a pressure applied via prescribed alternative gravimetric weights for alternative prescribed temperatures." In FDM technology, MFI will influence printing speed, layer bonding, print size accuracy, and surface smoothness.

The impact strength and tensile strength are the two commonly used properties to evaluate the toughness of a material. These properties can be improved through material modification technologies to meet certain application requirements.

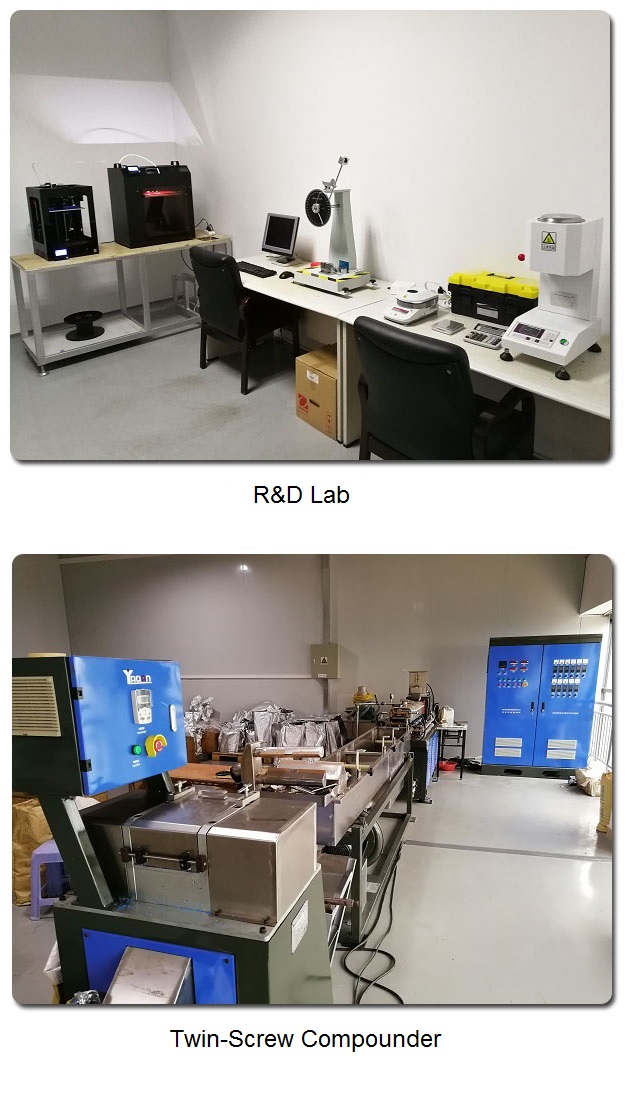

3D printer filaments are application-oriented. A specific application will determine the priorities among these properties. Therefore, modifications of the raw materials are necessary to meet the requirements. Instead of acquiring modified materials from suppliers, we choose to develop our own technology know-how. We think the In-House R&D capability is the key to manufacturing our filaments with consistent quality and stable supply.

Friendly Links :

Copyright © 2015-2018 Shenzhen Color Rich 3D Technology Co., Ltd..All Rights Reserved.

online service